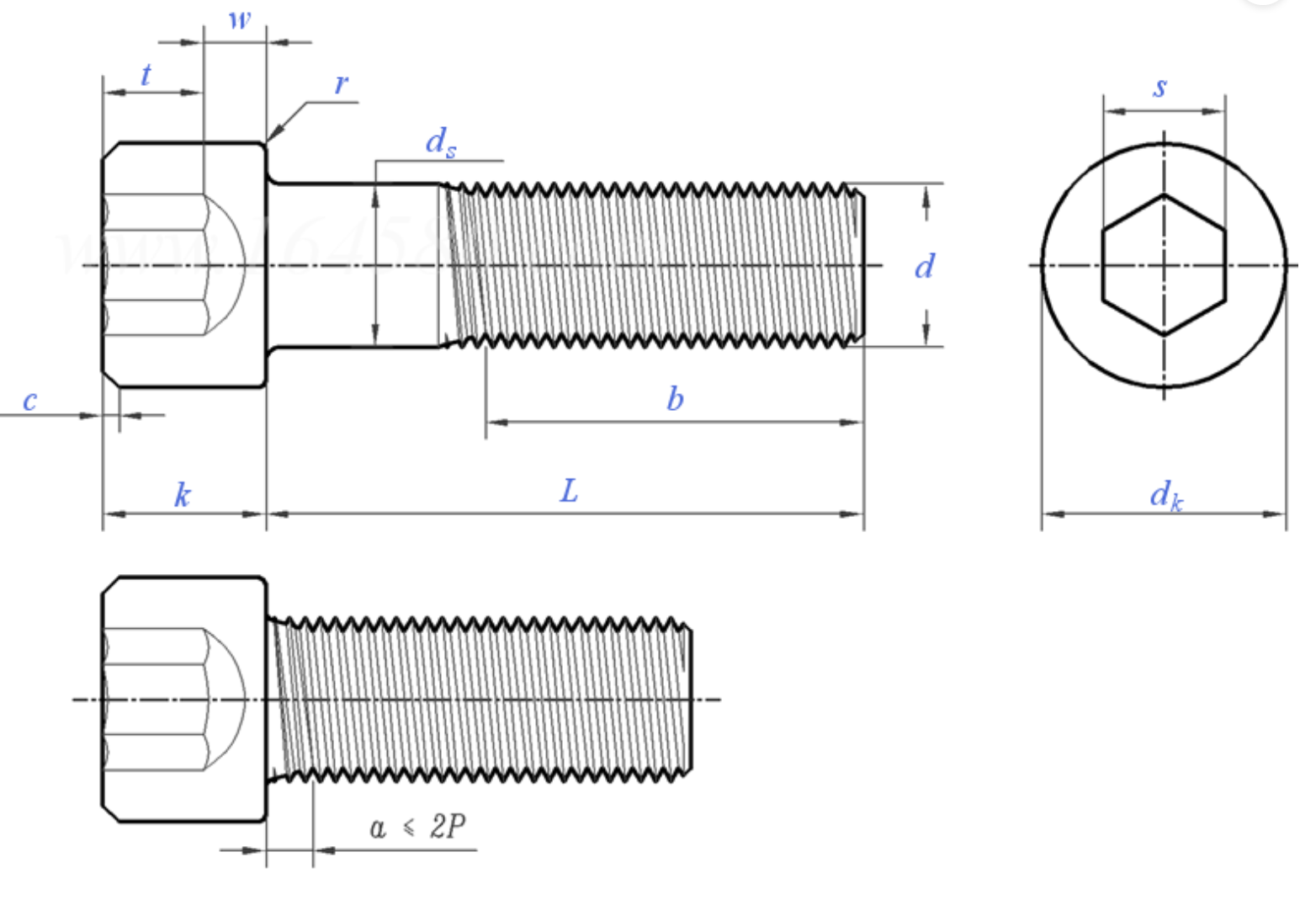

ASME B18.3 Hex Socket Cap Head Screw ASTM A574 F837

ASME B18.3 Hex Socket Cap Head Screw ASTM A574 F837

Inkcazo

KHAWULEZAImpendulo

KHAWULEZAUcaphulo

KHAWULEZAUkuhanjiswa

ILUNGELE UKUTHUMELA NGENQANABA

10000+ SKU kwindawo yokugcina impahla

Sizibophelela kwizinto ze-RTS:

70% izinto ezizisiweyo phakathi kweentsuku ezi-5

80% izinto ezizisiweyo phakathi kweentsuku ezisi-7

90% izinto ezizisiweyophakathi kweentsuku ezili-10

Iiodolo ezininzi, nceda uqhagamshelane nenkonzo yabathengi

| Ubungakanani | 0# | 1# | 2# | 3# | 4# | 5# | 6# | 8# | 10# | 12# | 1/4 | 5/16 | ||

| d | Umsonto Dia | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.3125 | |

| PP | UNC | - | 64 | 56 | 48 | 40 | 40 | 32 | 32 | 24 | 24 | 20 | 18 | |

| UNF | 80 | 72 | 64 | 56 | 48 | 44 | 40 | 36 | 32 | 28 | 28 | 24 | ||

| UNEF | - | - | - | - | - | - | - | - | - | 32 | 32 | 32 | ||

| ds | Ubukhulu=Esibizo | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.3125 | |

| Min | 0.0568 | 0.0695 | 0.0822 | 0.0949 | 0.1075 | 0.1202 | 0.1329 | 0.1585 | 0.184 | 0.2095 | 0.2435 | 0.3053 | ||

| dk ① | Max | 0.096 | 0.118 | 0.14 | 0.161 | 0.183 | 0.205 | 0.226 | 0.27 | 0.312 | 0.324 | 0.375 | 0.469 | |

| Min | 0.091 | 0.112 | 0.134 | 0.154 | 0.176 | 0.198 | 0.216 | 0.257 | 0.298 | 0.314 | 0.354 | 0.446 | ||

| k | Max | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.216 | 0.25 | 0.312 | |

| Min | 0.057 | 0.07 | 0.083 | 0.095 | 0.108 | 0.121 | 0.134 | 0.159 | 0.185 | 0.21 | 0.244 | 0.306 | ||

| s | Ngobizo | 0.05 | 0.062 | 0.078 | 0.078 | 0.094 | 0.094 | 0.109 | 0.141 | 0.156 | 0.156 | 0.188 | 0.25 | |

| t | Min | 0.025 | 0.031 | 0.038 | 0.044 | 0.051 | 0.057 | 0.064 | 0.077 | 0.09 | 0.103 | 0.12 | 0.151 | |

| b | Min | 0.5 | 0.62 | 0.62 | 0.62 | 0.75 | 0.75 | 0.75 | 0.88 | 0.88 | 0.88 | 1 | 1.12 | |

| c | Chamfer | Max | 0.004 | 0.005 | 0.008 | 0.008 | 0.009 | 0.012 | 0.013 | 0.014 | 0.018 | 0.022 | 0.025 | 0.033 |

| r | Chamfer | Max | 0.007 | 0.007 | 0.007 | 0.007 | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 | 0.01 | 0.01 | 0.01 |

| w | Min | 0.02 | 0.025 | 0.029 | 0.034 | 0.038 | 0.043 | 0.047 | 0.056 | 0.065 | 0.082 | 0.095 | 0.119 | |

| Ubungakanani | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | ||

| d | Umsonto Dia | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| PP | UNC | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 | |

| UNF | 24 | 20 | 20 | 18 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | ||

| UNEF | 32 | 28 | 28 | 24 | 24 | 20 | 20 | 20 | 18 | 18 | 18 | 18 | ||

| ds | Ubukhulu=Esibizo | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| Min | 0.3678 | 0.4294 | 0.4919 | 0.5538 | 0.6163 | 0.7406 | 0.8647 | 0.9886 | 1.1086 | 1.2336 | 1.3568 | 1.4818 | ||

| dk ① | Max | 0.562 | 0.656 | 0.75 | 0.843 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 | |

| Min | 0.54 | 0.631 | 0.725 | 0.827 | 0.914 | 1.094 | 1.291 | 1.476 | 1.665 | 1.852 | 2.038 | 2.224 | ||

| k | Max | 0.375 | 0.438 | 0.5 | 0.562 | 0.625 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | |

| Min | 0.368 | 0.43 | 0.492 | 0.554 | 0.616 | 0.74 | 0.864 | 0.988 | 1.111 | 1.236 | 1.36 | 1.485 | ||

| s | Ngobizo | 0.312 | 0.375 | 0.375 | 0.437 | 0.5 | 0.625 | 0.75 | 0.75 | 0.875 | 0.875 | 1 | 1 | |

| t | Min | 0.182 | 0.213 | 0.245 | 0.276 | 0.307 | 0.37 | 0.432 | 0.495 | 0.557 | 0.62 | 0.682 | 0.745 | |

| b | Min | 1.25 | 1.38 | 1.5 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.81 | 3.12 | 3.44 | 3.75 | |

| c | Chamfer | Max | 0.04 | 0.047 | 0.055 | 0.062 | 0.07 | 0.085 | 0.1 | 0.114 | 0.129 | 0.144 | 0.16 | 0.176 |

| r | Chamfer | Max | 0.01 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| w | Min | 0.143 | 0.166 | 0.19 | 0.214 | 0.238 | 0.285 | 0.333 | 0.38 | 0.428 | 0.475 | 0.523 | 0.57 | |

| Ubungakanani | 1-3/4 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | ||

| d | Umsonto Dia | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| PP | UNC | 5 | 4.5 | 4.5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| UNF | - | - | - | - | - | - | - | - | - | - | ||

| UNEF | - | - | - | - | - | - | - | - | - | - | ||

| ds | Ubukhulu=Esibizo | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| Min | 1.7295 | 1.978 | 2.228 | 2.4762 | 2.7262 | 2.9762 | 3.2262 | 3.4762 | 3.7262 | 3.9762 | ||

| dk ① | Max | 2.625 | 3 | 3.375 | 3.75 | 4.125 | 4.5 | 4.875 | 5.25 | 5.625 | 6 | |

| Min | 2.597 | 2.97 | 3.344 | 3.717 | 4.09 | 4.464 | 4.837 | 5.211 | 5.584 | 5.958 | ||

| k | Max | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | |

| Min | 1.734 | 1.983 | 2.232 | 2.481 | 2.73 | 2.979 | 3.228 | 3.478 | 3.727 | 3.976 | ||

| s | Ngobizo | 1.25 | 1.5 | 1.75 | 1.75 | 2 | 2.25 | 2.25 | 2.75 | 2.75 | 3 | |

| t | Min | 0.87 | 0.995 | 1.12 | 1.245 | 1.37 | 1.495 | 1.62 | 1.745 | 1.87 | 1.995 | |

| b | Min | 4.38 | 5 | 5.62 | 6.25 | 6.88 | 7.5 | 8.12 | 8.75 | 9.38 | 10 | |

| c | Chamfer | Max | 0.207 | 0.238 | 0.269 | 0.3 | 0.332 | 0.363 | 0.394 | 0.426 | 0.458 | 0.489 |

| r | Chamfer | Max | 0.02 | 0.02 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 | 0.036 |

| w | Min | 0.665 | 0.76 | 0.855 | 0.95 | 1.045 | 1.14 | 1.235 | 1.33 | 1.425 | 1.52 | |

Inkcazo yeenkcukacha

Ngokobulukhuni be-screw wire, i-tension, amandla emveliso njalo njalo, kukho ukuhlelwa kwebakala le-hexagon socket bolt, oko kukuthi, inqanaba le-hexagon socket bolt. Iimveliso ezahlukeneyo kunye nezixhobo ziyafuneka ukuba zibe namabakala ahlukeneyo eebholiti ze-hex ezihambelana nazo. Iibholiti ze-hex zonke zinala mabanga alandelayo:

Iibholiti ze-hexagon zesokethi zohlulwe zibe ziibholiti eziqhelekileyo neziphakamileyo ngokomgangatho webakala. Iibholiti eziqhelekileyo ze-hex socket zibhekisela kwiklasi ye-4.8, i-hex socket bolts yamandla aphezulu ibhekisela kwiklasi ye-8.8 okanye ngaphezulu, kuquka iklasi 10.9 kunye neklasi ye-12.9. Iibholiti ze-hex zebanga le-12.9 zidla ngokuba zizikrufu zentloko yesokethi ye-HEX emnyama ene-knurling, umbala wendalo kunye neoyile.

Umgangatho wokusebenza we-hex socket bolts yokudibanisa isakhiwo sentsimbi yi-3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, njl. Kukho ngaphezu kwe-10 amabakala, phakathi kwazo iibholiti zebanga le-8.8 nangaphezulu zenziwe nge-carbonated medium-heallow metal, okanye i-carbonated medium-heallow metal, okanye i-carbonated medium-heallow metal, ezibizwa ngokubanzi ngokuba ziibholiti zamandla aphezulu, kwaye ezinye zibizwa ngokuba ziibholiti eziqhelekileyo. Ileyibhile yomgangatho wokusebenza webholithi yenziwe ngamacandelo amabini, ngokulandelelanayo amele ixabiso lamandla okuqina kunye nomyinge webuckling wemathiriyeli yebholithi.

Ukupakisha

Ngathi

* Lo mzobo ulandelayo uchonga ii-incoterms ezahlukeneyo zorhwebo. Nceda ukhethe lowo ukhetha.

IMVELISO YOKUTHENGISA OKUSHISAYO

Umgangatho Wokuqala, Ukhuseleko luqinisekisiwe