DIN7991 Hex Socket Countersunk Screw IBanga leCarbon Steel Zinc ePlated Grade 8.8 10.9

DIN7991 Hex Socket Countersunk Screw IBanga leCarbon Steel Zinc ePlated Grade 8.8 10.9

Inkcazo

KHAWULEZAImpendulo

KHAWULEZAUcaphulo

KHAWULEZAUkuhanjiswa

ILUNGELE UKUTHUMELA NGENQANABA

10000+ SKU kwindawo yokugcina impahla

Sizibophelela kwizinto ze-RTS:

70% izinto ezizisiweyo phakathi kweentsuku ezi-5

80% izinto ezizisiweyo phakathi kweentsuku ezisi-7

90% izinto ezizisiweyophakathi kweentsuku ezili-10

Iiodolo ezininzi, nceda uqhagamshelane nenkonzo yabathengi

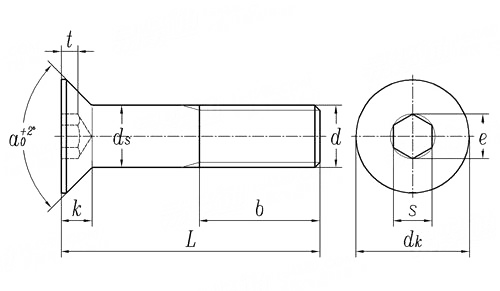

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | I-pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | intlawulo.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60 ° | 60 ° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Ubukhulu=Esibizo | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Ubukhulu=Esibizo | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Ngobizo | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Ubukhulu=Esibizo | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Inkcazo yeenkcukacha

Izibophelelo zokuqina eziphezulu ziya kuvelisa ukuqaqamba xa zifakwe igalvanized. Kufuneka ingqalelo ekhethekileyo.

I-Hydrogen embrittlement idla ngokubonakaliswa ngokulibaziseka ukuphuka phantsi koxinzelelo. Kubekho imithombo yemoto, iiwasha, izikrufu, izithonga zamashiti kunye nezinye iindawo ezifakwe amazimba, kwiiyure ezimbalwa emva kokuba indibano yaphukile, umlinganiselo wokwaphuka wama-40% ~ 50%. Kwinkqubo yokusebenzisa iinxalenye ze-cadmium-plated zemveliso ekhethekileyo, kwakukho i-batch crack fracture, kwaye ingxaki engundoqo yelizwe yasonjululwa kwaye inkqubo engqongqo ye-dehydrogenation yenziwe. Ukongeza, kukho ezinye embrittlement hydrogen alubonisi isenzeko ukulibaziseka ukwaphuka, ezifana: electroplating hanger (ucingo lwentsimbi, ucingo lobhedu) ngenxa yamaxesha amaninzi electroplating kunye pickling plating, Ukungena hydrogen kubi kakhulu, ngokufuthi kubonakala ekusebenziseni ugoso iya kwenzeka brittle fracture phenomenon; I-mandrel yompu, emva kwamaxesha amaninzi e-chroming, yawa phantsi yaza yaphuka; Ezinye iindawo ezicinyiweyo (uxinzelelo olukhulu lwangaphakathi) ziya kuqhekeka xa zikhetha. Ezi nxalenye zine-hydrogenated kakhulu kwaye ziqhekeka ngaphandle koxinzelelo lwangaphandle, olungasayi kuphinda lusetyenziswe ukubuyisela ubunzima bokuqala nge-dehydrogenation.

Ukuphakama kwamandla ezinto eziphathekayo, lukhulu uvakalelo lwe-hydrogen embrittlement. Le ngcamango esisiseko ekufuneka icaciswe ngabachwephesha bonyango lomphezulu xa bequlunqa iinkcukacha zenkqubo ye-electroplating. Iintsimbi ezinamandla okuqina σb>105kg/mm2 ezifunwa yimigangatho yamazwe ngamazwe kufuneka zibe phantsi koxinzelelo lwangaphambili kunye nonyango lwe-post-plating dehydrogenation ngokufanelekileyo. Ishishini lenqwelomoya laseFransi lifuna unyango oluhambelanayo lwe-dehydrogenation kumalungu entsimbi anamandla esivuno σs>90kg/mm2.

Ngenxa yembalelwano elungileyo phakathi kokuqina kwentsimbi kunye nokuqina, kuyaqondakala kwaye kulula ukugweba uvakalelo lwe-hydrogen embrittlement yezinto ngobulukhuni kunokuba ngamandla. Ngenxa yokuba umzobo ogqibeleleyo wemveliso kunye nenkqubo yomatshini kufuneka imakwe ngobulukhuni bentsimbi. Kwi-electroplating, safumanisa ukuba ukuqina kwentsimbi ejikeleze i-HRC38 yaqala ukubonisa umngcipheko wokuqhekeka kwe-hydrogen embrittlement. Kwiindawo ezingaphezulu kune-HRC43, i-dehydrogenation kufuneka ithathelwe ingqalelo emva kokubekwa. Xa ukuqina malunga ne-HRC60, unyango lwe-dehydrogenation kufuneka lwenziwe ngokukhawuleza emva konyango lwangaphezulu, ngaphandle koko iindawo zentsimbi ziya kuqhekeka kwiiyure ezimbalwa.

Ukupakisha

Ngathi

* Lo mzobo ulandelayo uchonga ii-incoterms ezahlukeneyo zorhwebo. Nceda ukhethe lowo ukhetha.

IMVELISO YOKUTHENGISA OKUSHISAYO

Umgangatho Wokuqala, Ukhuseleko luqinisekisiwe