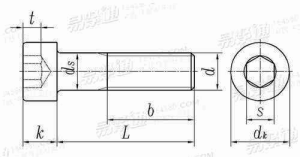

DIN912 Hex Socket Cup Head Screw M3-M30/carbon steel / grade 12.9

DIN912 Hex Socket Cup Head Screw M3-M30/carbon steel / grade 12.9

Inkcazo

KHAWULEZAImpendulo

KHAWULEZAUcaphulo

KHAWULEZAUkuhanjiswa

ILUNGELE UKUTHUMELA NGENQANABA

10000+ SKU kwindawo yokugcina impahla

Sizibophelela kwizinto ze-RTS:

70% izinto ezizisiweyo phakathi kweentsuku ezi-5

80% izinto ezizisiweyo phakathi kweentsuku ezisi-7

90% izinto ezizisiweyophakathi kweentsuku ezili-10

Iiodolo ezininzi, nceda uqhagamshelane nenkonzo yabathengi

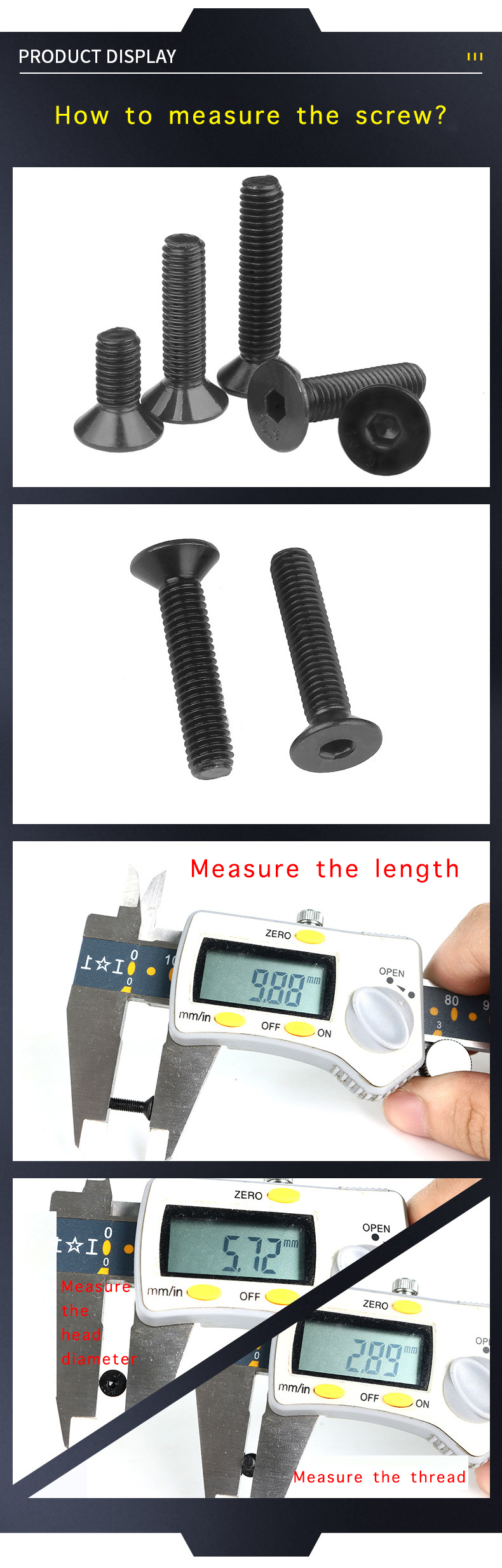

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | Umsonto orhabaxa | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Umsonto olungileyo | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Intambo entle kakhulu | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Ixabiso lereferensi | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | Ubukhulu (Bulula) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| UMax (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Ngobizo | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Ubude bomsonto=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | ||

| P | Umsonto orhabaxa | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 | |

| Umsonto olungileyo | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| Intambo entle kakhulu | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | ||

| b | Ixabiso lereferensi | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 | |

| dk | Ubukhulu (Bulula) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 | |

| UMax (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | ||

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | ||

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | ||

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | ||

| s | Ngobizo | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 | |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | ||

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | ||

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 | |

| Ubude bomsonto=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | ||

Inkcazo yeenkcukacha

Izibophelelo zokuqina eziphezulu ziya kuvelisa ukuqaqamba xa zifakwe igalvanized. Kufuneka ingqalelo ekhethekileyo.

I-Hydrogen embrittlement idla ngokubonakaliswa ngokulibaziseka ukuphuka phantsi koxinzelelo. Kubekho imithombo yemoto, iiwasha, izikrufu, izithonga zamashiti kunye nezinye iindawo ezifakwe amazimba, kwiiyure ezimbalwa emva kokuba indibano yaphukile, umlinganiselo wokwaphuka wama-40% ~ 50%. Kwinkqubo yokusebenzisa iinxalenye ze-cadmium-plated zemveliso ekhethekileyo, kwakukho i-batch crack fracture, kwaye ingxaki engundoqo yelizwe yasonjululwa kwaye inkqubo engqongqo ye-dehydrogenation yenziwe. Ukongeza, kukho ezinye embrittlement hydrogen alubonisi isenzeko ukulibaziseka ukwaphuka, ezifana: electroplating hanger (ucingo lwentsimbi, ucingo lobhedu) ngenxa yamaxesha amaninzi electroplating kunye pickling plating, Ukungena hydrogen kubi kakhulu, ngokufuthi kubonakala ekusebenziseni ugoso iya kwenzeka brittle fracture phenomenon; I-mandrel yompu, emva kwamaxesha amaninzi e-chroming, yawa phantsi yaza yaphuka; Ezinye iindawo ezicinyiweyo (uxinzelelo olukhulu lwangaphakathi) ziya kuqhekeka xa zikhetha. Ezi nxalenye zine-hydrogenated kakhulu kwaye ziqhekeka ngaphandle koxinzelelo lwangaphandle, olungasayi kuphinda lusetyenziswe ukubuyisela ubunzima bokuqala nge-dehydrogenation.

Ukuphakama kwamandla ezinto eziphathekayo, lukhulu uvakalelo lwe-hydrogen embrittlement. Le ngcamango esisiseko ekufuneka icaciswe ngabachwephesha bonyango lomphezulu xa bequlunqa iinkcukacha zenkqubo ye-electroplating. Iintsimbi ezinamandla okuqina σb>105kg/mm2 ezifunwa yimigangatho yamazwe ngamazwe kufuneka zibe phantsi koxinzelelo lwangaphambili kunye nonyango lwe-post-plating dehydrogenation ngokufanelekileyo. Ishishini lenqwelomoya laseFransi lifuna unyango oluhambelanayo lwe-dehydrogenation kumalungu entsimbi anamandla esivuno σs>90kg/mm2.

Ngenxa yembalelwano elungileyo phakathi kokuqina kwentsimbi kunye nokuqina, kuyaqondakala kwaye kulula ukugweba uvakalelo lwe-hydrogen embrittlement yezinto ngobulukhuni kunokuba ngamandla. Ngenxa yokuba umzobo ogqibeleleyo wemveliso kunye nenkqubo yomatshini kufuneka imakwe ngobulukhuni bentsimbi. Kwi-electroplating, safumanisa ukuba ukuqina kwentsimbi ejikeleze i-HRC38 yaqala ukubonisa umngcipheko wokuqhekeka kwe-hydrogen embrittlement. Kwiindawo ezingaphezulu kune-HRC43, i-dehydrogenation kufuneka ithathelwe ingqalelo emva kokubekwa. Xa ukuqina malunga ne-HRC60, unyango lwe-dehydrogenation kufuneka lwenziwe ngokukhawuleza emva konyango lwangaphezulu, ngaphandle koko iindawo zentsimbi ziya kuqhekeka kwiiyure ezimbalwa.

Ukupakisha

Ngathi

* Lo mzobo ulandelayo uchonga ii-incoterms ezahlukeneyo zorhwebo. Nceda ukhethe lowo ukhetha.

Handan Yongnian Hongji Machinery Parts Co., Ltd.

Kwiminyaka yakutshanje, siye sandisa amashishini kumazwe angaphezu kwama-20, iVietnam, iThailand, i-Indonesia, iMalaysia, iBangladesh, iIndiya, iPakistan, i-Egypt, i-Kuwait, i-UAE, uMzantsi Afrika, iJamani, iRashiya, iUnited States, iCanada, iMexico, njalo njalo.

Iqabane lethu

IMVELISO YOKUTHENGISA OKUSHISAYO

Umgangatho Wokuqala, Ukhuseleko luqinisekisiwe