DIN912 T2 Copper Hex Socket Cup Screw Head

DIN912 T2 Copper Hex Socket Cup Screw Head

Inkcazo

KHAWULEZAImpendulo

KHAWULEZAUcaphulo

KHAWULEZAUkuhanjiswa

ILUNGELE UKUTHUMELA NGENQANABA

10000+ SKU kwindawo yokugcina impahla

Sizibophelela kwizinto ze-RTS:

70% izinto ezizisiweyo phakathi kweentsuku ezi-5

80% izinto ezizisiweyo phakathi kweentsuku ezisi-7

90% izinto ezizisiweyophakathi kweentsuku ezili-10

Iiodolo ezininzi, nceda uqhagamshelane nenkonzo yabathengi

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | Umsonto orhabaxa | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Umsonto olungileyo | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Intambo entle kakhulu | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Ixabiso lereferensi | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | Ubukhulu (Bulula) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| UMax (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Ngobizo | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Ubude bomsonto=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | Umsonto orhabaxa | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Umsonto olungileyo | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Intambo entle kakhulu | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Ixabiso lereferensi | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | Ubukhulu (Bulula) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| UMax (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Ngobizo | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Ubude bomsonto=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

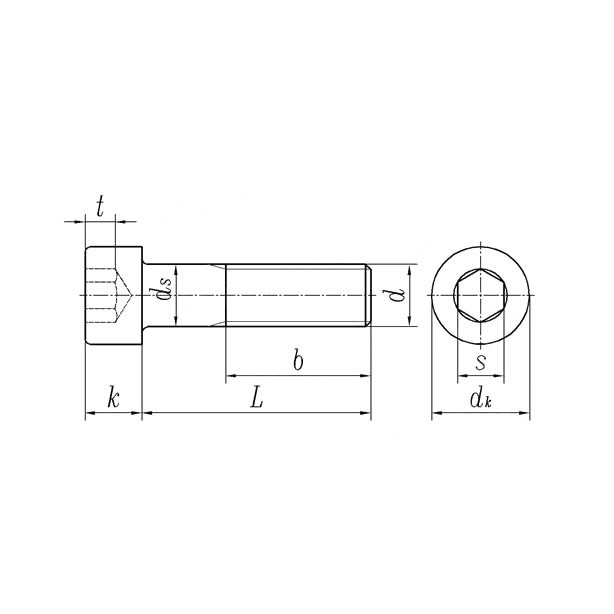

Umzobo weenkcukacha

Yintoni umahluko phakathi kobhedu, ubhedu, ubhedu?

Ubhedu, iBrass kunye neBronze, ngenye indlela eyaziwa ngokuba yi "Red Metals", inokubukeka ngokufanayo ekuqaleni. Kodwa eneneni banomahluko omkhulu kwizinto, ukusebenza njalo njalo.

Ubhedu

I-Copper isetyenziselwa uluhlu olubanzi lweemveliso ngenxa ye-conductivity egqwesileyo yombane kunye ne-thermal, amandla amahle, ukubunjwa kakuhle kunye nokuchasana nokubola. Izifakelo zemibhobho kunye nemibhobho zidla ngokuveliswa kwezi zinyithi ngenxa yokunganyangeki kokuhlwa kwazo. Ziyakwazi ukuthengiswa ngokukhawuleza kwaye ziboshwe, kwaye ezininzi zinokudityaniswa ngegesi eyahlukeneyo, i-arc kunye neendlela zokuchasa. Ziyakwazi ukugudiswa kwaye zinyanzeliswe phantse nakuphi na ukuthungwa okufunwayo kunye nokucwebezela.

Kukho amabakala eCopper engafakwanga, kwaye anokwahluka kwisixa sobumdaka obuqulethwe. Amabakala obhedu angenawo oksijini asetyenziswa ngokuthe ngqo kwimisebenzi apho kufuneka khona ukuqhuba okuphezulu kunye ne-ductility.

Enye yezona zinto zibalulekileyo zobhedu kukukwazi ukulwa neebhaktheriya. Emva kovavanyo olubanzi lwe-antimicrobial yi-Arhente yoKhuseleko lokusiNgqongileyo, kwafunyaniswa ukuba ii-alloys zobhedu ezingama-355, kubandakanywa neebrasi ezininzi, zafunyanwa zibulala ngaphezu kwe-99.9% yeebhaktheriya kwiiyure ezimbini zoqhagamshelwano. Ukungcoliswa okuqhelekileyo kwafunyaniswa ukuba kungaphazamisi ukusebenza kwe-antimicrobial.

Izicelo zobhedu

Ubhedu lwaluyenye yezona zimbiwa zokuqala ezafunyanwayo. AmaGrike namaRoma ayesenza izixhobo zokuhombisa, yaye kukho neenkcukacha zembali ezibonisa ukusetyenziswa kobhedu ukuze kuhlanjululwe amanxeba nokuhlambulula amanzi okusela. Namhlanje ifumaneka kakhulu kwizinto zombane ezifana ne-wiring ngenxa yokukwazi ukuqhuba ngokufanelekileyo umbane.

Ubhedu

Ubhedu ikakhulu yi-alloy equkethe ubhedu kunye ne-zinc eyongeziweyo. Iibrasi zinokuba nezixa ezahlukeneyo ze-zinc okanye ezinye izinto ezongeziweyo. Le mixube ehlukeneyo ivelisa uluhlu olubanzi lweepropati kunye nokwahluka kombala. Izixa ezongeziweyo ze-zinc zibonelela ngezinto eziphuculweyo zamandla kunye ne-ductility. Ubhedu lunokuba nombala obomvu ukuya kumthubi kuxhomekeke kubungakanani be-zinc eyongezwe kwi-alloy.

Ukuba umxholo we-zinc wobhedu usuka kwi-32% ukuya kwi-39%, uya kuba nokwandisa amandla okusebenza okushushu kodwa ukusebenza okubandayo kuya kunqunyulwa.

Ukuba ubhedu luqulethe ngaphezu kwe-39% ye-zinc (umzekelo - i-Muntz Metal), iya kuba namandla aphezulu kunye ne-ductility ephantsi (kwiqondo lokushisa).

Izicelo zobhedu

I-Brass isetyenziswa ngokuqhelekileyo kwiinjongo zokuhombisa ngokuyinhloko ngenxa yokufana kwayo negolide. Ikwayinto eqhelekileyo ukwenza izixhobo zomculo ngenxa yokusebenza kwayo okuphezulu kunye nokuqina.

Ubhedu

I-Bronze yi-alloy equkethe ngokuyinhloko ubhedu kunye nokongezwa kwezinye izithako. Kwiimeko ezininzi isithako esongeziweyo siyi-tin, kodwa i-arsenic, i-phosphorus, i-aluminium, i-manganese, kunye ne-silicon ingasetyenziselwa ukuvelisa iipropati ezahlukeneyo kwizinto eziphathekayo. Zonke ezi zithako zivelisa i-alloy enzima kakhulu kunobhedu kuphela.

Ibronzi ibonakala ngombala wayo omdaka-bugolide. Ungawubona kwakhona umahluko phakathi kobhedu nobhedu kuba ubhedu luya kuba namakhonkco abuthathaka kumphezulu walo.

Usetyenziso lweBronze

Ubhedu lusetyenziswa ekwakhiweni kwemifanekiso eqingqiweyo, izixhobo zomculo kunye neendondo, nakwizicelo zemizi-mveliso ezifana ne-bushings kunye neebheringi, apho intsimbi yayo ephantsi kwi-friction yentsimbi iluncedo. Ibronzi nayo ineentshukumo zaselwandle ngenxa yokunganyangeki kwayo ekudlekeni.

Ukupakisha

Ngathi

* Lo mzobo ulandelayo uchonga ii-incoterms ezahlukeneyo zorhwebo. Nceda ukhethe lowo ukhetha.

IMVELISO YOKUTHENGISA OKUSHISAYO

Umgangatho Wokuqala, Ukhuseleko luqinisekisiwe